MACHINE

PARK

Cutting, bending and welding of metal sheets

comprehensive sheet metal processing

Only metal furniture that meets specific technical requirements can be used to furnish industrial plants, medical practices, social rooms and other such interiors. This is why we use a modern machinery park for professional metal processing in our daily work. Our equipment allows us to carry out professional sheet metal cutting and bending, as well as welding, pyrolysis or UV printing.

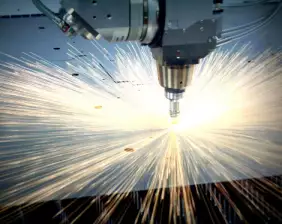

TRULASER CELL 7040 FOR LASER PROCESSING

The TruLaser Cell 7040 is a high-end laser processing device. The laser beam is produced on a solid state, the so-called laser seed, and is amplified in special glass fibres. Thanks to this solution, the fibre laser has a wavelength of 1.064 micrometres, which makes it possible to achieve a very small focus diameter.

TruLaser Cell 7040 for the execution of a wide variety of tasks in:

- 2D and 3D cutting, including cutting of flat workpieces, profiles as well as welded and welded parts

- welding

- making two- or three-dimensional objects

- single or series production

TRULASER 3030 LASER CUTTING MACHINE

We provide laser cutting services on a Trumpf TruLaser 3030 laser cutting machine, which:

- allows workpieces and parts of any shape to be cut in sheet metal, guaranteeing 100% repeatability. The high quality of the cut edge makes it possible to produce a component that does not require further finishing,

- guarantees the use of state-of-the-art technological programmes and CNC numerical control, resulting in extremely high laser cutting accuracy of 0.1 mm.

Modern technological programmes allow maximum material utilisation and optimised laser cutting processes. Laser cutting is non-contact, allowing components to be cut from ground and polished metal sheets without disturbing the surface. Constant maintenance of the grates minimises the occurrence of chipping.

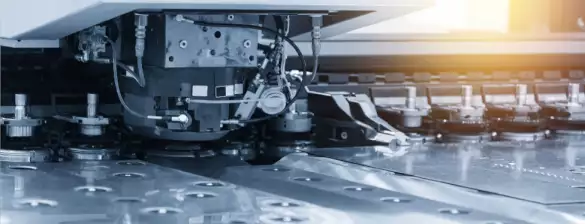

TC200R TRUMPF MACHINING CENTRE

The TC200R is used for machining workpieces with even surfaces by die-cutting and vibratory punching. Die-cutting is a technique for mechanically cutting materials using a punch and die as part of industrial production. These methods can be used to produce cut-outs and contours of any shape and size (within the machine's working range).

SALVAGNINI P2XE BENDING CENTRE

GÖTENEDS FLANGING AND FOLDING MACHINE

Machining of sheet metal is completed by the new GÖTENEDS flanging and folding machine of Futura Plus series. The patented structure of the machine with rotary clamping beam is characterised by universal application, whereas the folding beam is driven by two motors assembled at the ends of the beam.

Back table is provided with 4 tilting pneumatically extended stops, thank to which specific dimensions can be very quickly positioned. Thanks to unique structure of the front section with elastic ends of the stops, they can be placed approx. 2 mm away from the bend edge. Therefore, milling of the stops at the lower beam is not required, and no impression is left on the material.

WELDERS, PRESS BRAKES, FIXED SPOT – WELDING MACHINES

We use MIG, MAG and TIG welders, enabling us to produce precise welds. In the MIG method, we use argon or helium as the shielding gas, while the MAG method makes use of CO2 or a mix of CO2 and argon as the active gas. We weld aluminium alloys, and heat and acid resistant metal sheets using the TIG method. We can produce airtight welds, whose quality is verified using special chemical agents. Thanks to our advanced welding machines, we can produce any shape whatsoever, ensuring the highest possible quality of our welded structures

Currently, the company is carrying out a number of investment projects that will enable it to purchase state-of-the-art metalworking machines and implement innovative technologies. In the nearest future, we plan to purchase advanced automatic bending machines and other metal forming, cutting and coating equipment.

These projects are expected to increase process automation, improve the quality of our products, and boost our manufacturing capacity.

FIBER INSPIRE 1530 F 0.4 LASER CUTTER

Fiber iNspire 1530 F 4.0 laser cutter is a technologically advanced, very precise and dynamic machine. It cuts black sheet metal, stainless steel, non-ferrous metals and aluminium.

The machine is dedicated for mass production, where high level of cutting precision is indispensable. It can be used to cut elements of electric engines and other elements of complex shapes.

Discussed cutter is provided with one of the fastest real-time operating system on the market. Cutting speed up to 150m/min. and 6G laser cutting acceleration guarantee high reliability, perfect edges, cutting reproducibility of 0.03 [mm/m] and exceptional cutting precision of 0.05 [mm/m].

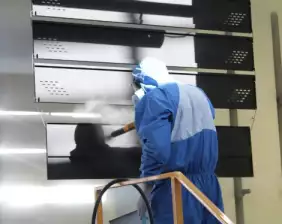

Powder coating

highest quality powder coating.

The high quality of metal furniture consists not only of good and well thought-out design. To ensure that the solutions we offer are also durable, we supplement our service with powder coating. Industrial, school or public furnishings are painted using modern lines that guarantee the highest quality of coating.

OPTI CENTER ITW GEMA PAINT LINE

We carry out the powder coating service using an automatic spray booth and the latest generation of the OptiCenter powder management system from ITW GEMA.

The technology we use achieves very good coating results and is optimally suited to coating both small and large (max. up to 2,000 mm H x 1,400 mm W x 1,000 mm D) series parts.

The spray booth is equipped with a control system for twelve guns and manipulators, as well as painting axes and fresh paint dosing, which ensures full coordination of the entire painting process. Our paint spray booth is additionally equipped with two separate powder gun stations for manual adding of paint in places difficult to access for the automatic machine. The smooth dosing and continuous supply of a constant quantity of paint results in a uniform film thickness. The process is supervised via the central unit's operating panel, which guarantees optimum setting of the course and time of painting individual workpieces, and ensures excellent coating quality and high repeatability of the painted workpieces.

OPTI IDEAL-LINE PAINT LINE

The large-size oven booths and dryers used in the new Ideal-Line paint line enable us to paint workpieces of large dimensions (up to 2500 mm H x 1500 mm W x 4000 mm L with a maximum weight of 250 kg), which significantly increases our existing technological capabilities.

The technology we use achieves very good coating results and is optimally suited to coating both small and large (max. up to 2,000 mm H x 1,400 mm W x 1,000 mm D) series parts.

The spray booth is equipped with a control system for twelve guns and manipulators, as well as painting axes and fresh paint dosing, which ensures full coordination of the entire painting process. Our paint spray booth is additionally equipped with two separate powder gun stations for manual adding of paint in places difficult to access for the automatic machine. The smooth dosing and continuous supply of a constant quantity of paint results in a uniform film thickness. The process is supervised via the central unit's operating panel, which guarantees optimum setting of the course and time of painting individual workpieces, and ensures excellent coating quality and high repeatability of the painted workpieces.

Printing on furniture

and more

UV printing on furniture is the ideal solution for all those who like unusual solutions and want to give their space a unique character.

The possibility of printing any design on any flat surface helps to give a unique atmosphere to the furnished interior.

It is also for those who have the idea of creating individualised furnishings in the space they create.

SUMMA CUT D120 R PLOTTER

The high-quality, reliable Summa Cut D120 R cutting plotter is equipped with a trailing cutter and a special cutter for thick films, which, in combination with high pressure force, guarantees precise contour cutting (contour cutting) even in thick films (e.g. for sandblasting). The plotter is equipped with the OPOS positioning system, which cuts any shape with great precision, smoothing out bends and curves at the same time. Thanks to the plotter, we can cut out any lettering, numbers, graphics and other patterns, which can later be applied to various materials.

UV SWISS Q PRINT ORYX

The UV printer is a large-format, hybrid printer guaranteeing high-quality digital prints that are several times more resistant to external conditions than standard solvent prints.

The printer allows the primer to be applied selectively or to the entire print piece, including to the edges. The precise arrangement of the printed formats ensures excellent quality of each print.

It is capable of printing almost any material available on the market, including materials with irregular shapes and surfaces (e.g. plywood).